T-3002-PRO

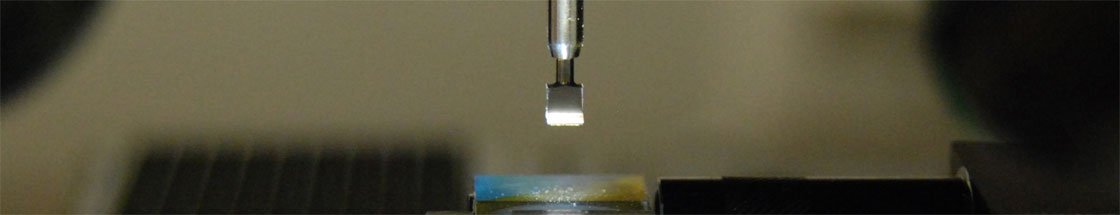

The T-3002-PRO series is Tresky’s most flexible die bonding platform. The systems can run all basic functions as well as the industries most advanced applications by adding a wide range of available options. As with all of Tresky’s products, the PRO incorporates True Vertical Technology™ which guarantees parallelism between chip and substrate at any bond height. Together with superior ergonomics the PRO platform is the industry’s most sophisticated system in its class and with the new PC software even easier to operate.

The T-3002-PRO is a Chip Bonder with programmable and motorised Z-axis. It is also equiped with Tresky's proven die ejector system for pick-up from wafer.

Download

T-5300

Manual Bonder with semi auto. process capabilities

Tresky’s T-5300 is the flagship of our Die Bonders and adds a motorized, programmable Z-axis, with our True Vertical Technology™, to the repertoire of the universal T-5100, making it extra useful for repetitive processes in small-scale production, where

operator influence must be minimized. The T-5300 really shines in applications with highest

precision requirements, such as flip-chip, or eutectic placement. An optional high-resolution

beam splitter unit allows sub-micron placement accuracy.

Download

T-5300-W

Manual Bonder with semi auto. process capabilities

Wafer Handling capability

The T-5300-W version offers the same flexibility as the T-5300 with the added benefit of being able to handle wafers with Tresky's electric die ejection system, which is located under the main table located. The system has all the basic features to run the most advanced applications in the industry. For this you can add a wide range of available options. Like all Tresky products, the T-5100-W includes True Vertical Technology™, which guarantees parallelism between chip and substrate at any connection height. Along with superior ergonomics, the platform is the industry's most advanced system in its class and is even easier to use with the new intuitive software.

The T-5300-W version features the same flexibility than the T-5100 and has the additional advantage of handling a wafer of up to 200mm which sits below the main table with Tresky’s elctrical die ejection system.

Typical and customized applications

• Die sorting from wafer into waffle packs or gel packs

• Die attach with adhesive (stamped or dispensed)

• 3D packaging of MEMS, MOEMS, VCSEL, Photonics, ...

• High-precision placement with visual adjustment by beam-splitter unit for look-up inspection of

edges, corners or patterns, e.g. for laser bars

• Flip-Chip with ultrasonic die attach

• Flip-Chip with adhesives or anisotropic foils

• Sensor assembly

• UV curing of die attach

• Eutectic bonding of AuSi, Copper Pillar and others

• Ultrasonic bonding on a curved surface

Download

Any questions or interest in a online product demonstration?

Fabio Cocca - your sales contact at Dr. Tresky AG would be happy to talk to you personally. Give him a call or simply use our enquiry form.

+41 44 772 19 41

Please note our privacy policy.