Dr. Tresky AG

tresky_at_tresky.com

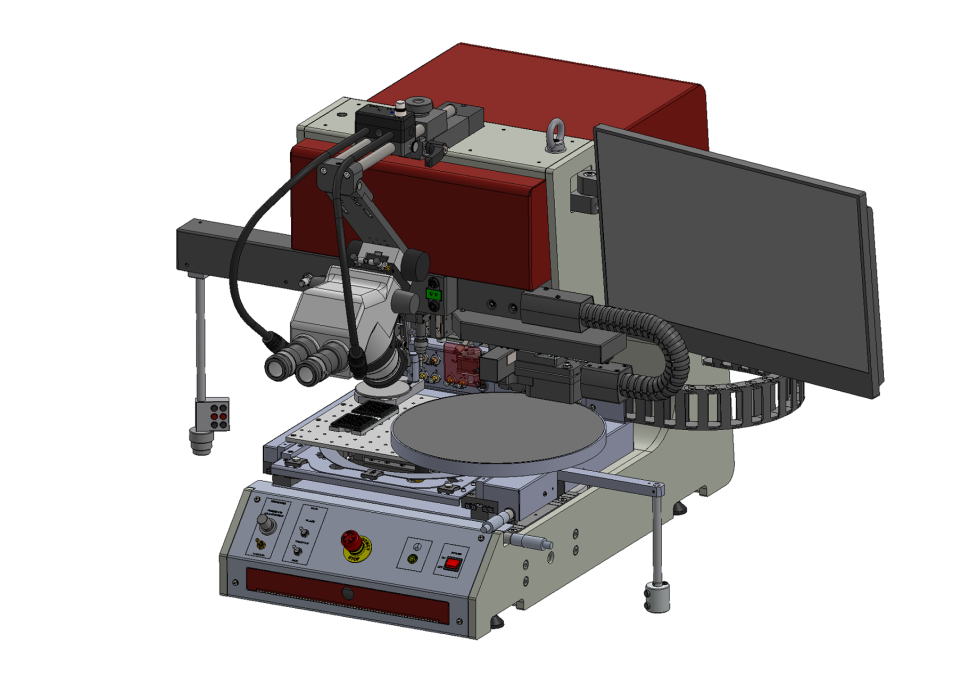

Hybrid Bonding / Die-to-Wafer Bonding (up to 12”)

April, 30 2025

Hybrid bonding is a reliable, permanent connection that merges a dielectric bond (SiOx) with embedded metal (Cu), creating high-performance interconnections. Known in the industry as Direct Bond Interconnect (DBI), this method enhances fusion bonding by incorporating metal pads within the bonding interface, enabling face-to-face wafer connections.

At Tresky, we also integrate plasma cleaning (e.g., with Surfx) into the bonding process for improved results. Hybrid bonding facilitates Die-to-Wafer (D2W) and Wafer-to-Wafer (W2W) connections through precisely aligned copper pads. While W2W Hybrid Bonding has been widely used in image sensors for years, there is an increasing push to advance D2W Hybrid Bonding. This progression will drive heterogeneous integration, offering an efficient and flexible solution to directly connect dies of varying sizes, functions, and design rules.

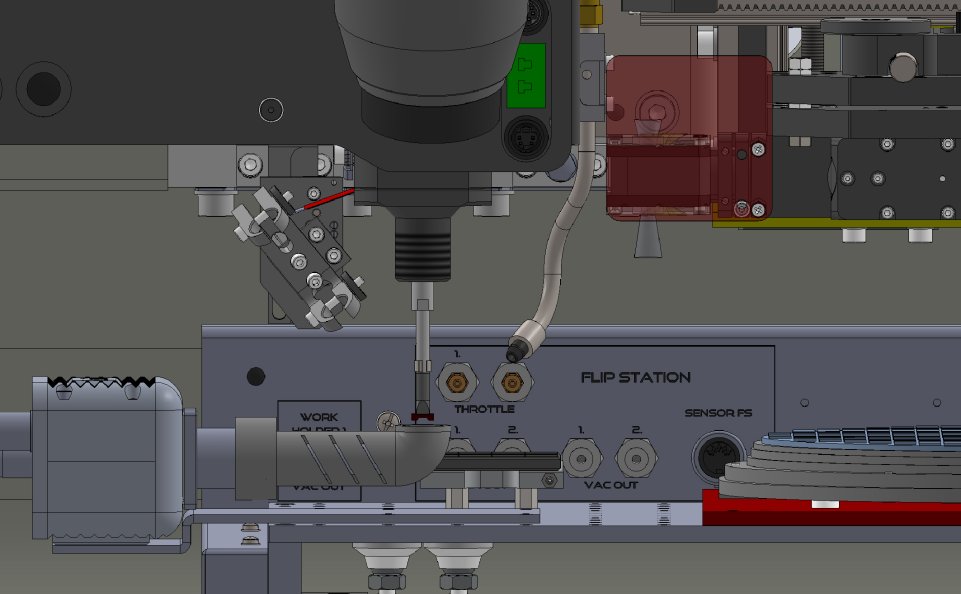

Picked-up Chip over Plasma beam