General

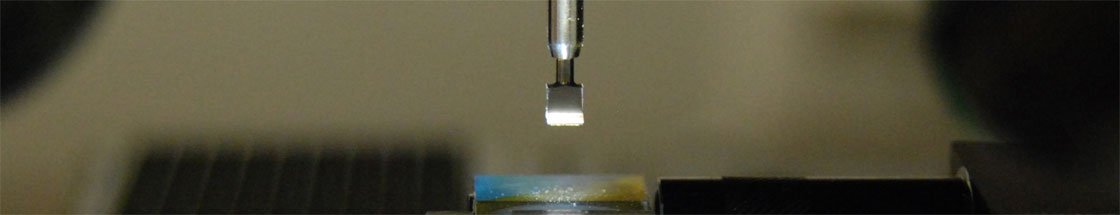

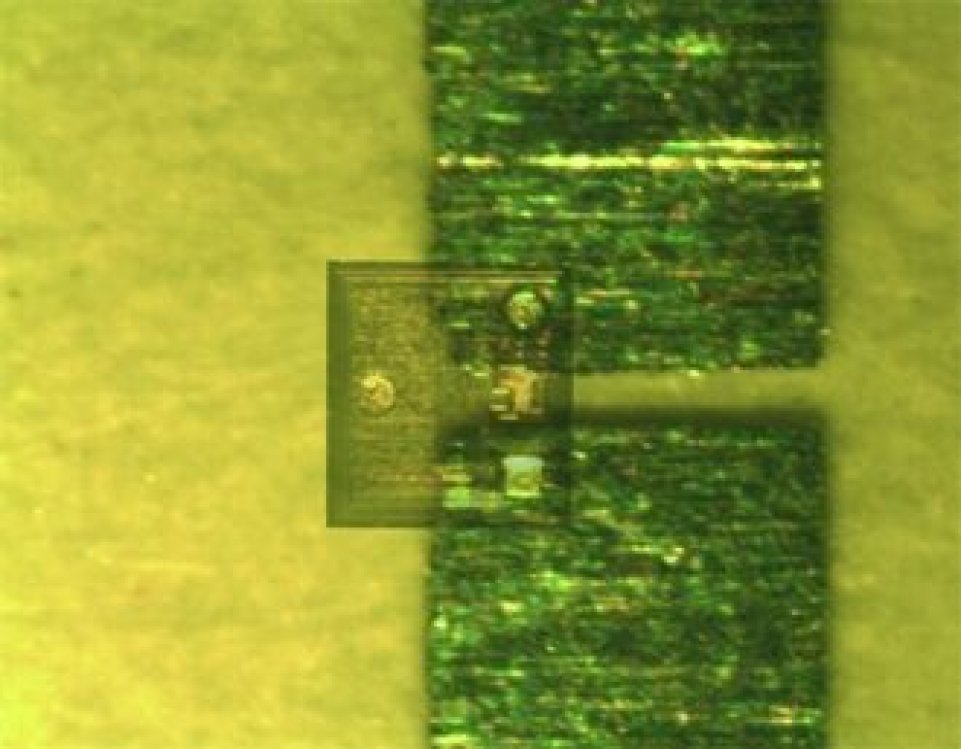

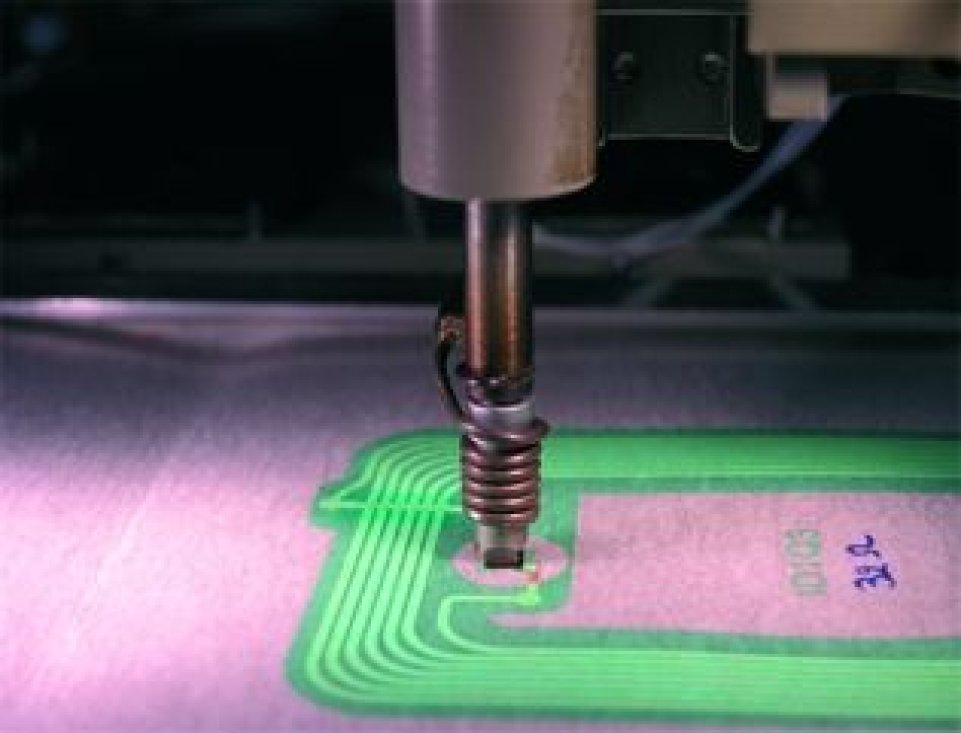

(Radio-frequency Identification) tags contain at least two parts. One is an integrated circuit for storing and processing information, modulating and demodulating a (RF) signal, and other specialized functions. The second is an antenna for receiving and transmitting the signal. Tresky’s modular die bonding equipment delivers, once more, optimal perfomance in R&D and pre-production assembly as e.g.: Bonding of a Flip-Chip to Antenna.

Flexibility

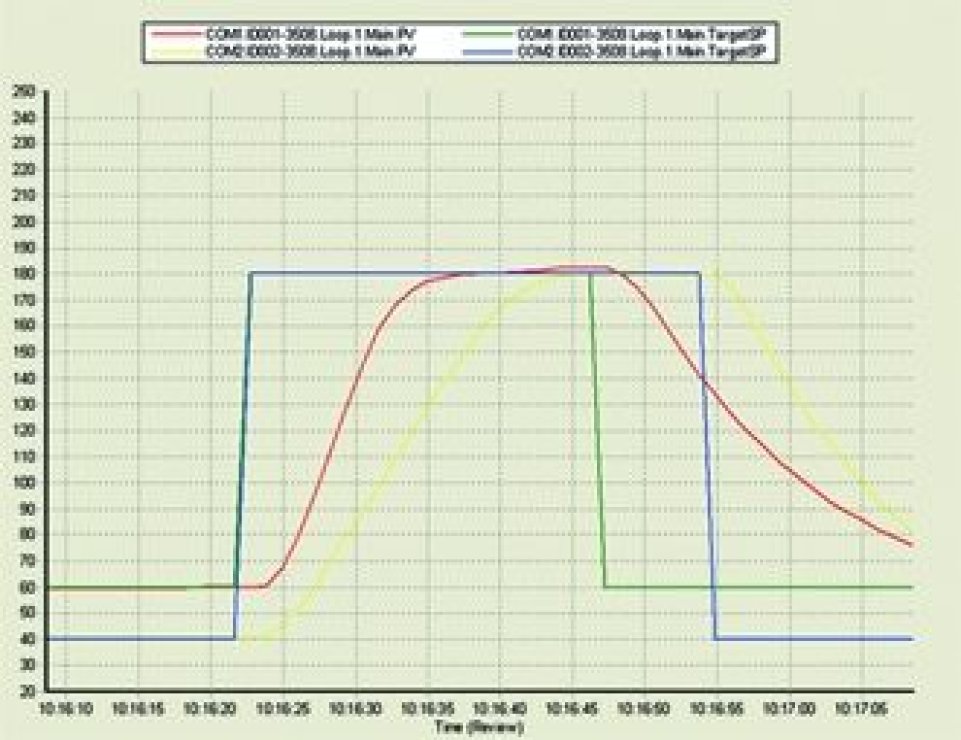

Tresky’s T-5000series allows different RFID bonding processes, such as adhesive or ultrasonic bonding. Process parameters can be easely adjusted for optimized results. Temperature, time and force can be adjusted respectively programed independently.

Technical Parameters

Position Accuracy:

10micron (or less)

Bonding Parameters:

Force 20g - 400g and time up to 2-4sec. on final curing temperature.

Temperature:

Adjustable temp. profile for chip and antenna up to 200°C with ramping speed up to 18°C/Sec. for adhesive technologies only.

Various Processes

Process - Adhesive Tech. (ACP Anisotropic Conductive Paste)

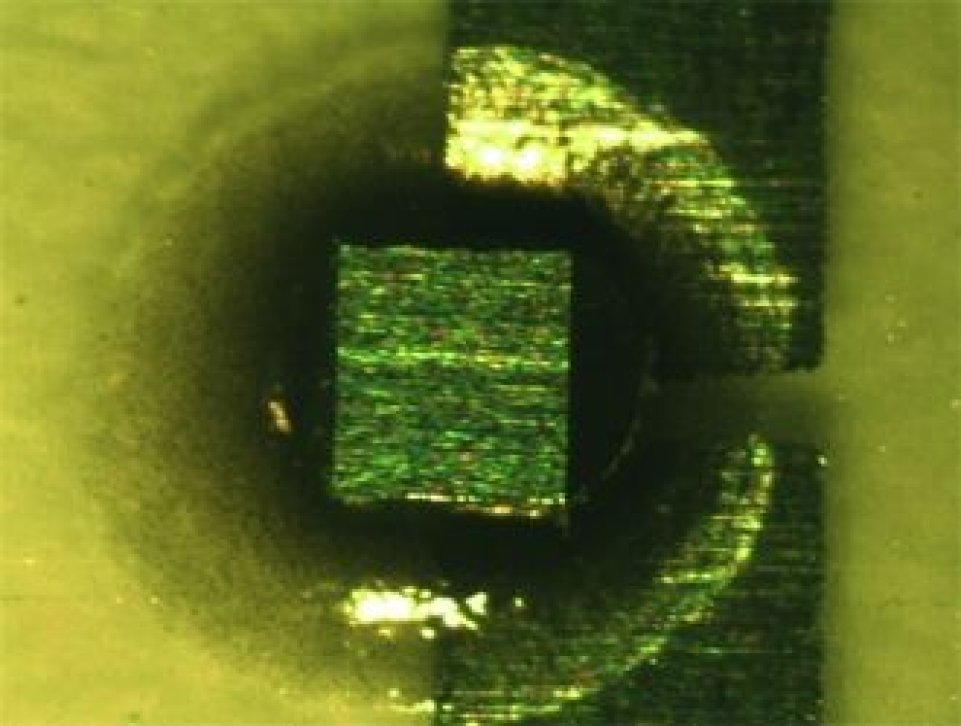

Dispense ACP glue on antenna. Electroless bumped chip, aligned by beam splitter, placed into glue and cured.

Process - Adhesive Tech. (NCP Non Conductive Paste)

Dispense NCP glue on antenna. Stud bumped chip, aligned by beam splitter, placed into glue and cured.

Process - Ultrasonic

During placement, the ultrasonic energy is transfered to the chip contacts, where it is transformed into heat.

Any questions or interest in a online product demonstration?

Fabio Cocca - your sales contact at Dr. Tresky AG would be happy to talk to you personally. Give him a call or simply use our enquiry form.

+41 44 772 19 41

Please note our privacy policy.